Burner Controls

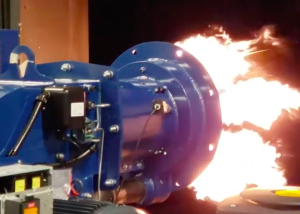

Boiler burner control technology has evolved considerably in the digital age. And rightly so – if the burner is the heart of the system, the burner control system is the brain.

The burner control serves three basic purposes: 1) It controls the supply of fuel according to the boiler’s load; 2) it controls the air supply according to the fuel consumption; and 3) it will shut off the burners in case of an emergency.

But even with advances in burner control technology, routine maintenance is important. Air temperature in a boiler room may change dramatically from day to night and from season to season, leading to changes in combustion efficiencies.

Routine maintenance of your burner control system will:

- Prevent breakdowns/downtime

- Maintain the highest level of efficiency

- Ensure safe operation

- Reduce emissions

- In HVAC applications, optimize the comfort level in your building

Annual maintenance is the minimum standard. At AB&M we recommend quarterly or monthly system assessments. Whether you’re doing the maintenance yourself or hiring the experienced pros at AB&M, here’s a checklist that keeps the burner control system operating at its maximum level:

- Inspect and clean the heat exchanger, igniter, atomizer, electrodes, and other components, if applicable

- Check pressures, vacuum readings, safety controls, and limits

- Measure, O2, CO2 levels and exhaust temperatures

- Tighten electrical connections

- Check start-up burner operation

- Minimize air leakage to ensure optimal combustion

- Perform a combustion efficiency test and make follow-up adjustments as needed

Another sometimes overlooked aspect to the boiler burner control system is using a controller that works with both primary and back-up fuel sources. There are many off-the-shelf component options available to meet such requirements.

To be certain your boiler’s burner control system is operating properly, contact us by calling 800-235-5377 or through our website at www.AmericanBoilerMech.com.